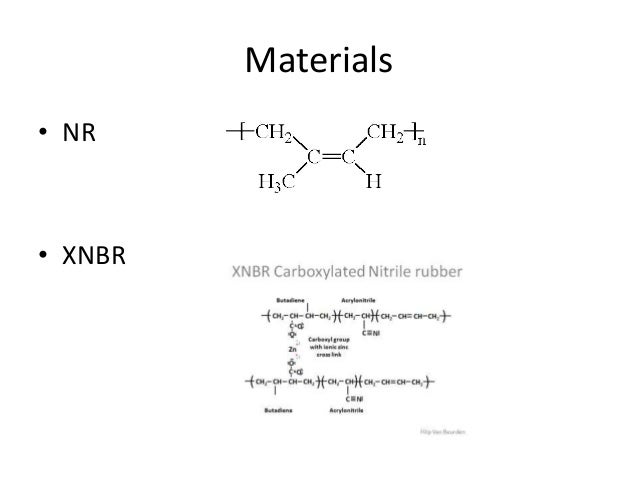

Carboxylated Nitrile Butadiene Rubber

Carboxylated nitrile xnbr carboxylated nitrile xnbr is a special type of nitrile polymer that exhibits enhanced tear and abrasion resistance.

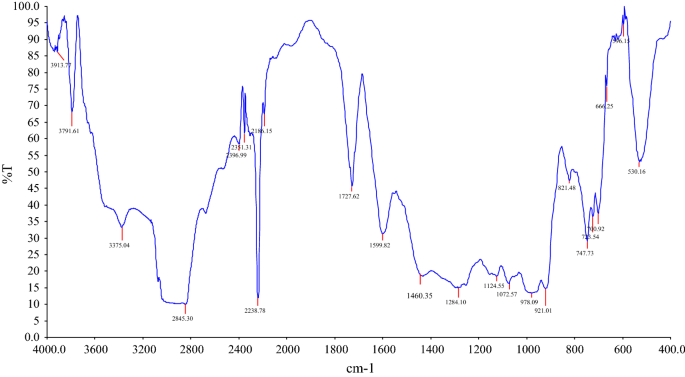

Carboxylated nitrile butadiene rubber. Contrary to that the resistance to water the. For this reason xnbr based materials are often specified for dynamic applications such as rod seals and rod wipers. Trade names include perbunan nipol krynac and europrene this rubber is unusual in being resistant to oil fuel and other chemicals. It is a highly carboxylated butadiene acrylonitrile polymer latex with a high nitrile content featuring a combination of excellent oil grease and hydrocarbon resistance toughness resilience and tear and abrasion resistance.

Highly saturated nitrile hsn temperature range. Whereas the oil and solvent resistance properties of the rubber will retain at the excellent. Excellent heat and oil resistance improved fuel and ozone resistance approximately 5x over nitrile good abrasion resistance. Xnbr carboxylated nitrile butadiene rubber.

Available hardness range shore a 50 95. Decreased elasticity at low temperatures with hydrogenation over standard nitrile. Tensile strength up to. Between 54 c and 135 c.

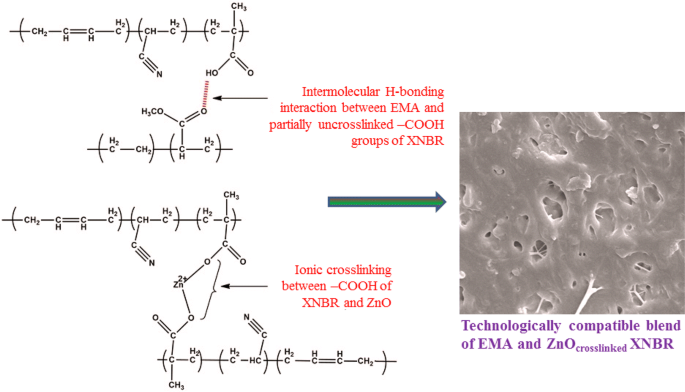

Produced by adding a carboxylic acid group to a nitrile rubber this material contains more cross linking points than the common nbr. Carboxylated nitrile butadiene rubber xnbr hydrogenated nitrile butadiene rubber hnbr or. The result is a major resistance to swelling and abrasion as well as higher tensile and breaking strengh. Carboxylated nitrile butadiene rubber xnbr is a special type of nitrile butadiene rubber nbr containing carboxyl functional groups which cause to exhibit enhanced tear and abrasion resistance 7.

Nychem n4000m carboxylated nitrile butadiene latex. Heat resistance up to 100 c 212 f with shorter life 121 c 250 f. Nbr is used in the automotive and aeronautical industry to make fuel and oil handling hoses seals grommets. Nychem n4000m one of our specialty emulsion offerings.

For assistance in identifying the appropriate polymer or material or to develop and formulate a xnbr or carboxylated nitirle rubber compound to meet your specific application and performance requirements please contact rahco rubber inc. Introducing carboxylic acid groups to the polymer backbone of nbr nitrile butadiene rubber significantly alters the rubber s properties extra crosslinks in the polymer creating a polymer matrix with significantly increased strength tear modulus and abrasion resistance at the expense of reduced compression set water resistance resilience and some low temperature properties. Buna n between 40 c and 135 c low temperature between 65 c and 120 c.