Centrifugal Air Compressor Advantages And Disadvantages

If you have any query regarding this article ask by commenting.

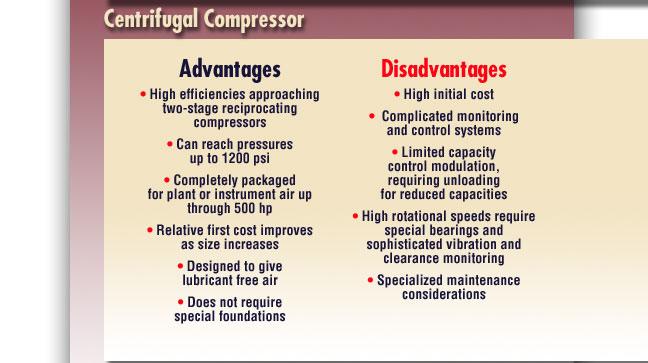

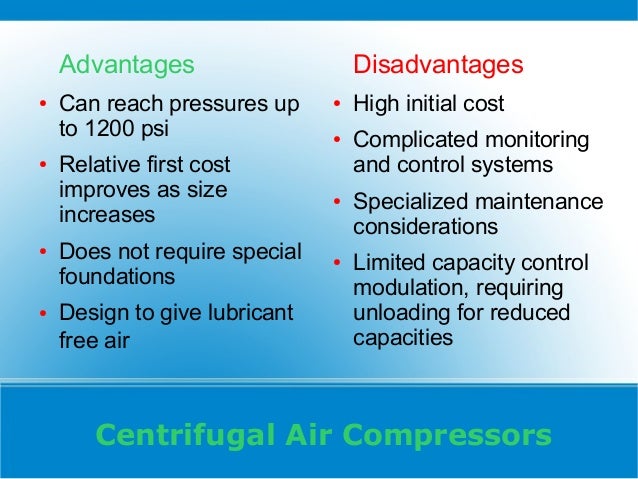

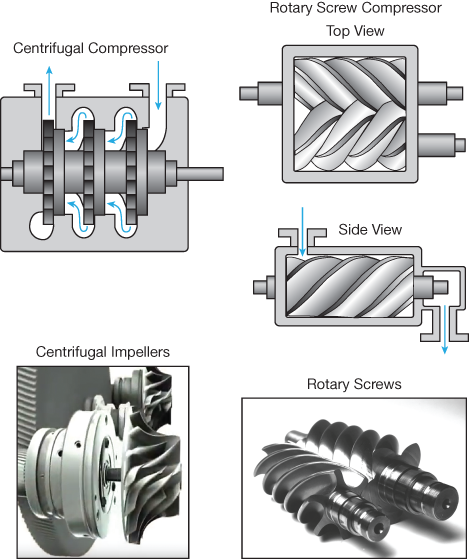

Centrifugal air compressor advantages and disadvantages. Advantages and disadvantages of air compressor types pros and cons of different air compressor types benefits and drawbacks of different air compressor types how to chose which air compressor is right for you. High speed requires quality bearing and sophisticated maintenance programs. They have fewer rubbing parts. High flow rate than the positive displacement.

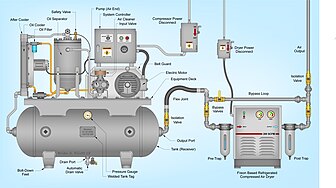

What are the disadvantages and advantages of axial and centrifugal compressors. Relatively routine maintenance procedures. Suitable for continuous compressed air supply such as cooling unit. The equipment is costly.

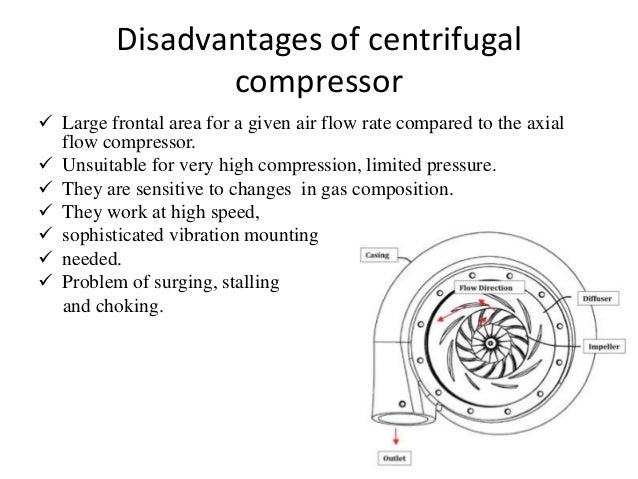

The oil free in nature. Disadvantages of centrifugal compressor large frontal area for a given air flow rate compared to the axial flow compressor. This is all about centrifugal compressor principle working construction types advantages disadvantages with its application. Efficient compression particularly with multi stage compressors.

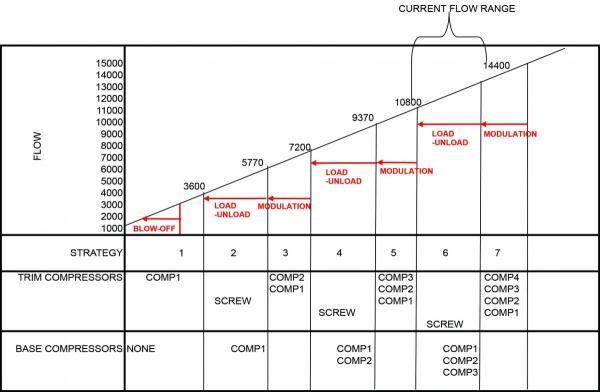

Subscribe our website for more informative articles. Suitable for continuous compressed air supply. Three step 0 50 100 percent or five step 0 25 50 75 100 percent capacity controls allowing efficient part load operation. Unsuitable for very high compression limited pressure.

Oil free air output. Belt driven centrifugal direct drive oil free portable reciprocating rotary screw single 2 stage vertical horizontal air compressors. They are sensitive to changes in gas composition.