Coefficient Of Thermal Expansion Butyl Rubber

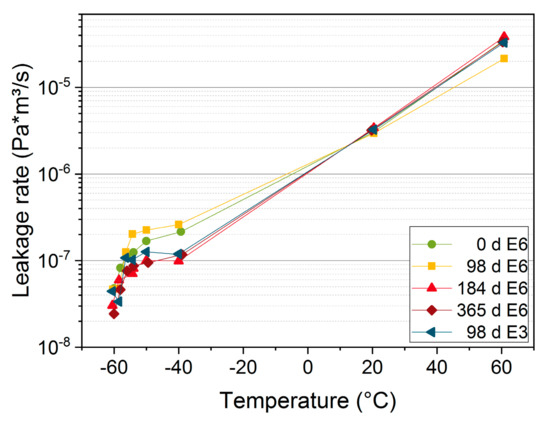

This occurrence is caused mainly by a decrease in thickness.

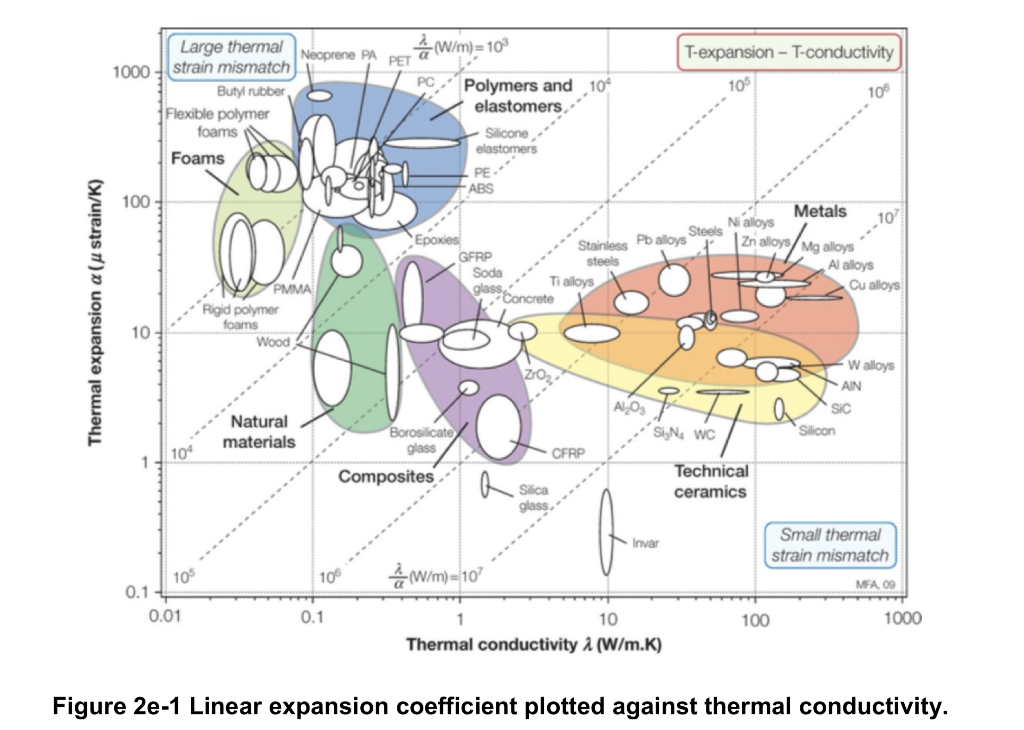

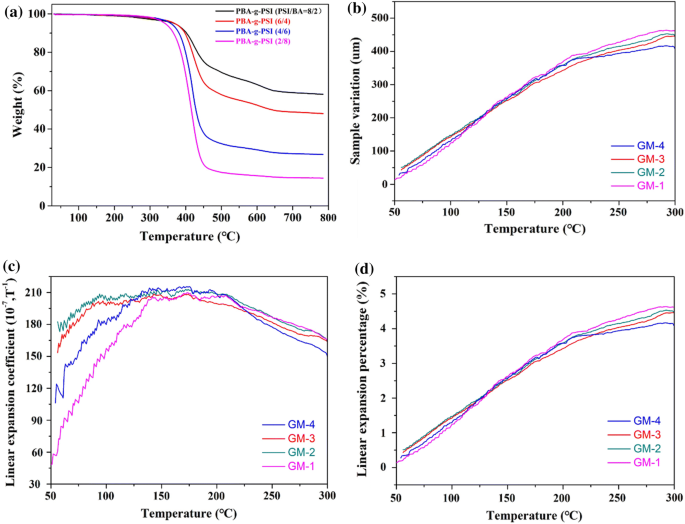

Coefficient of thermal expansion butyl rubber. Thermodynamics effects of work heat and energy on systems. Comparing this expansivity to that of steel 3 5 x e 05 k a tenfold difference one begins to understand the built in interfacial strain in a bonded rubber metal or composite. Find linear thermal expansion coefficient α and volumetric coefficient for thermal expansion β at 20 c for different material like brass copper concrete lead silver water and more linear thermal expansion coefficient α at 20 c for rubber is 77 x 10 6 c and volumetric coefficient for thermal expansion β at 20 c is 231 x. There have been instances where a seal has ruptured a steel gland due to expansion when heated.

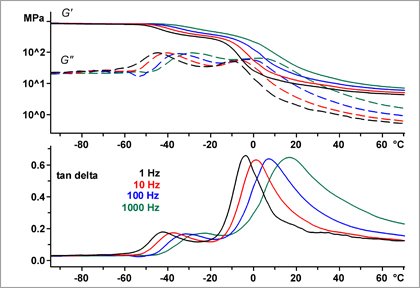

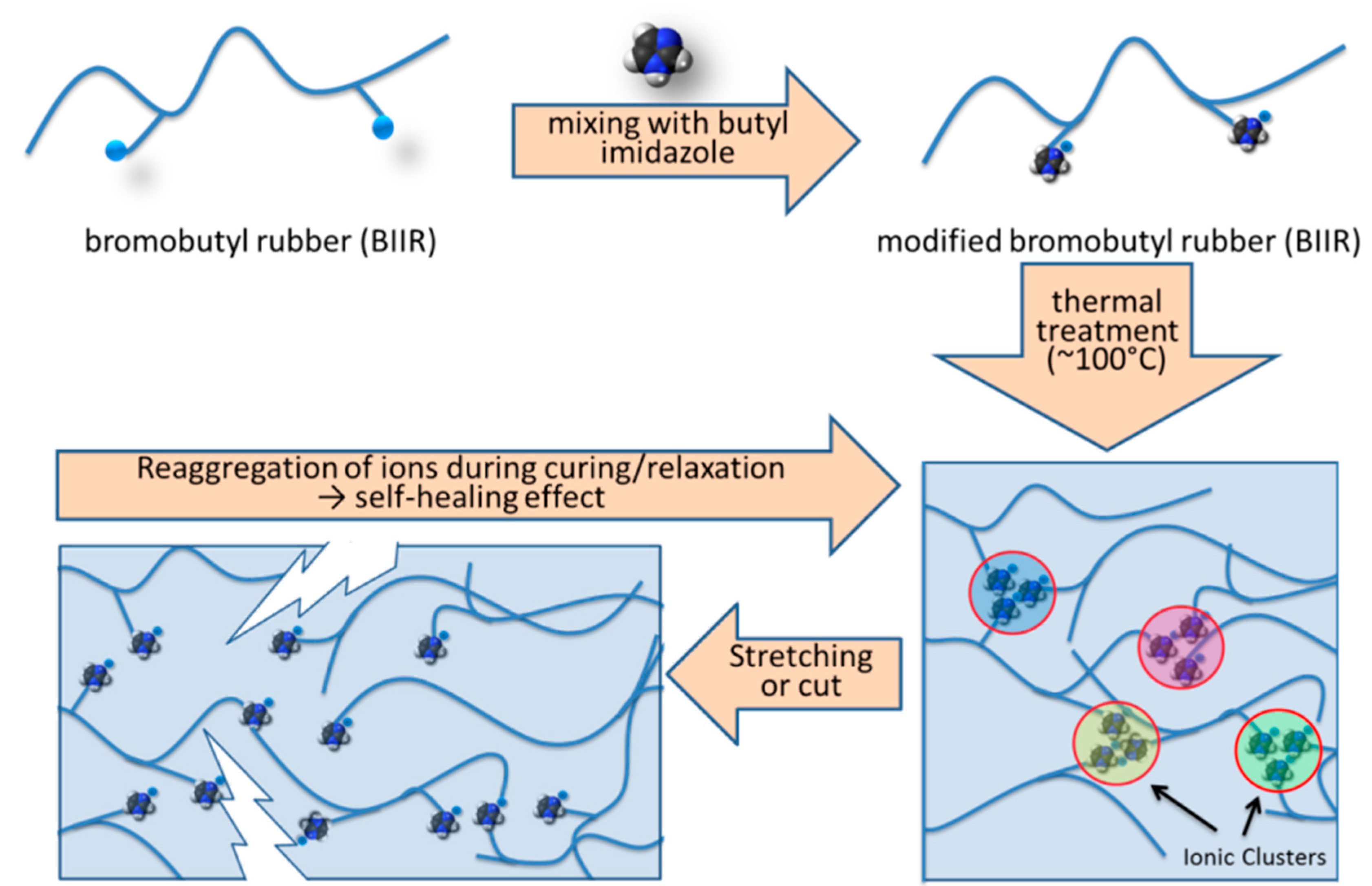

These forces are generated by thermal expansion of the rubber and or swelling effect of a fluid. Thermal expansion is the tendency of matter to change its shape area volume and density in response to a change in temperature usually not including phase transitions. When a substance is heated molecules begin to vibrate and move more usually creating more distance between themselves. Addition of fillers reduces the value slightly.

Temperature expansion thermal expansion of pipes and tubes stainless steel carbon steel copper plastics and more. Coefficient of thermal expansion silicone has a high thermal expansion coefficient and can be used as a temperature activation method or sensor in the design. Carbons 1 2 to 2 5 x 10 6 2 16 to 4 5 x 10. If the seal is completely confined and the gland is 100 filled the dominating force is the force of thermal expansion of the rubber.

List of thermal expansion coefficients cte for natural and engineered materials mse supplies is a leading supplier of high quality materials equipment and materials characterization services for advanced materials research and manufacturing. Temperature is a monotonic function of the average molecular kinetic energy of a substance. The coefficient of thermal expansion for elastomer is approximately 4 8 x 10e 04 k similar to a hydrocarbon liquid. This expansion is an advantage for sealing applications.

The user of these elastic materials should be aware that the final thermal resistance which is of course from an engineering point of view the more important parameter might change under pressure and temperature. Material properties material properties for gases fluids and solids densities specific heats viscosities and more. The overall coefficient is the linear thermal expansion in per degree. However the thermal conductivity might also change.

Abs pipes pressure ratings pressure ratings of.