Coefficient Of Thermal Expansion Natural Rubber

Temperature expansion thermal expansion of pipes and tubes stainless steel carbon steel copper plastics and more.

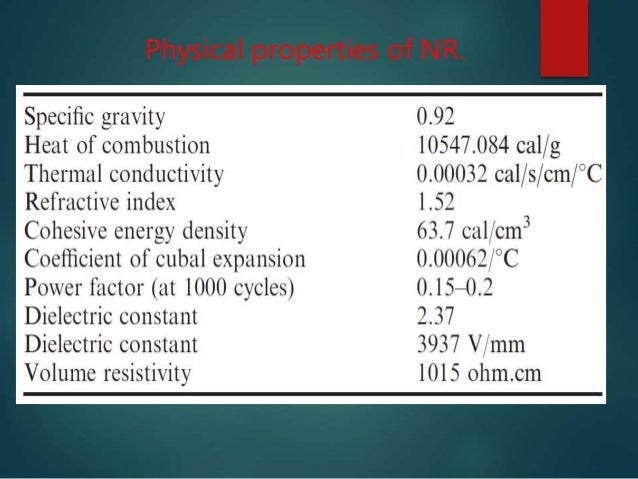

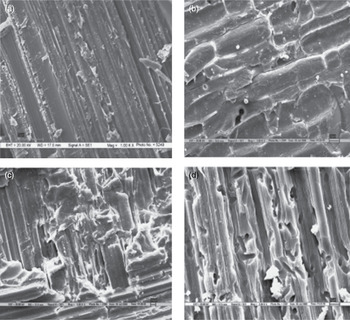

Coefficient of thermal expansion natural rubber. Thermal expansion is the tendency of matter to change its shape area volume and density in response to a change in temperature usually not including phase transitions. The coefficient of thermal expansion for elastomer is approximately 4 8 x 10e 04 k similar to a hydrocarbon liquid. α r t g 0 164. There have been instances where a seal has ruptured a steel gland due to expansion when heated.

Coefficient of thermal expansion silicone has a high thermal expansion coefficient and can be used as a temperature activation method or sensor in the design. Addition of fillers reduces the value slightly. Silicone rubber 190 0 x 10 6 342 0 x 10 6 mech. When a substance is heated molecules begin to vibrate and move more usually creating more distance between themselves.

The only thing that can happen which may look like the rubber is shrinking when heated is the evaporation of plasitsizers. We found that the boyer spencer rule often underestimates the expansion coefficient of the polymer in its rubber state and that the relation. Temperature is a monotonic function of the average molecular kinetic energy of a substance. These forces are generated by thermal expansion of the rubber and or swelling effect of a fluid.

The coefficient of thermal expansion is defined as the change in length or volume of a material for a unit change in temperature. The thermal expansion coefficients of a polymer in its rubber state can be estimated with the boyer spencer rule 3. Abs pipes pressure ratings pressure ratings of. α g t g 0 08.

Find linear thermal expansion coefficient α and volumetric coefficient for thermal expansion β at 20 c for rubber or for different material like brass copper concrete lead silver water and more. If the seal is completely confined and the gland is 100 filled the dominating force is the force of thermal expansion of the rubber. The overall coefficient is the linear thermal expansion in per degree. This expansion is an advantage for sealing applications.

Rubbers both natural and synthetic absolutely definitively have positive linear thermal expansion coefficients regardless of fillers plastisizers etc. Material properties material properties for gases fluids and solids densities specific heats viscosities and more. Comparing this expansivity to that of steel 3 5 x e 05 k a tenfold difference one begins to understand the built in interfacial strain in a bonded rubber metal or composite. Carbons 1 2 to 2 5 x 10 6 2 16 to 4 5 x 10.