Coefficient Of Thermal Expansion Of Rubber

Although the rubber has a high thermal expansion coefficient it was found that when the rubber domains are deformed into microlayers and co continuous with the plastic matrix the clte of the polymer alloy parallel to the microlayer.

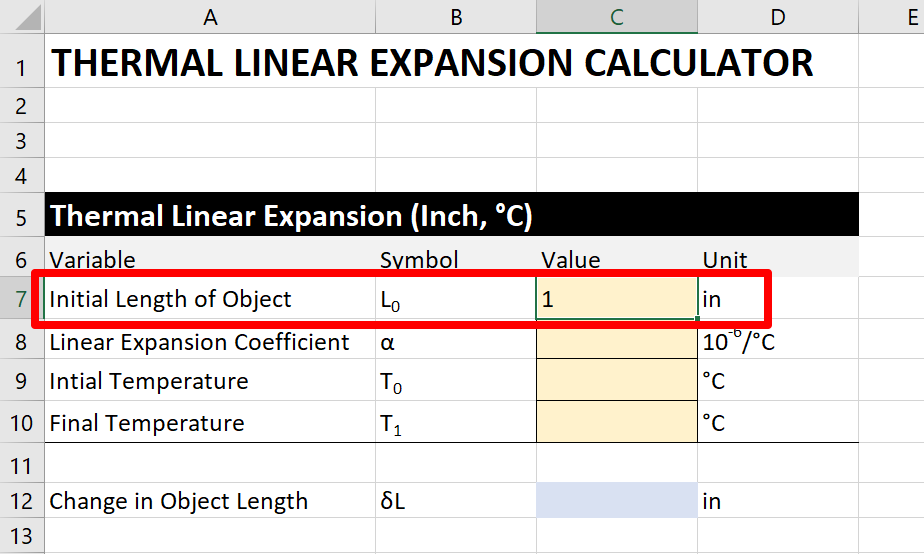

Coefficient of thermal expansion of rubber. Linear thermal expansion coefficient α at 20 c for rubber is 77 x 10 6 c and volumetric coefficient for thermal expansion β at 20 c is 231 x 10 6 c view full reference table. When a substance is heated molecules begin to vibrate and move more usually creating more distance between themselves. Temperature is a monotonic function of the average molecular kinetic energy of a substance. The coefficient of thermal expansion is used to determine the rate at which a material expands as a function of temperature.

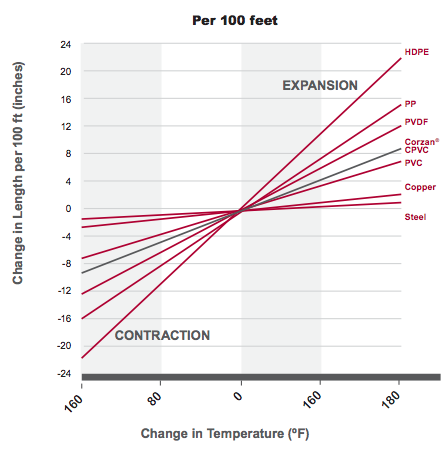

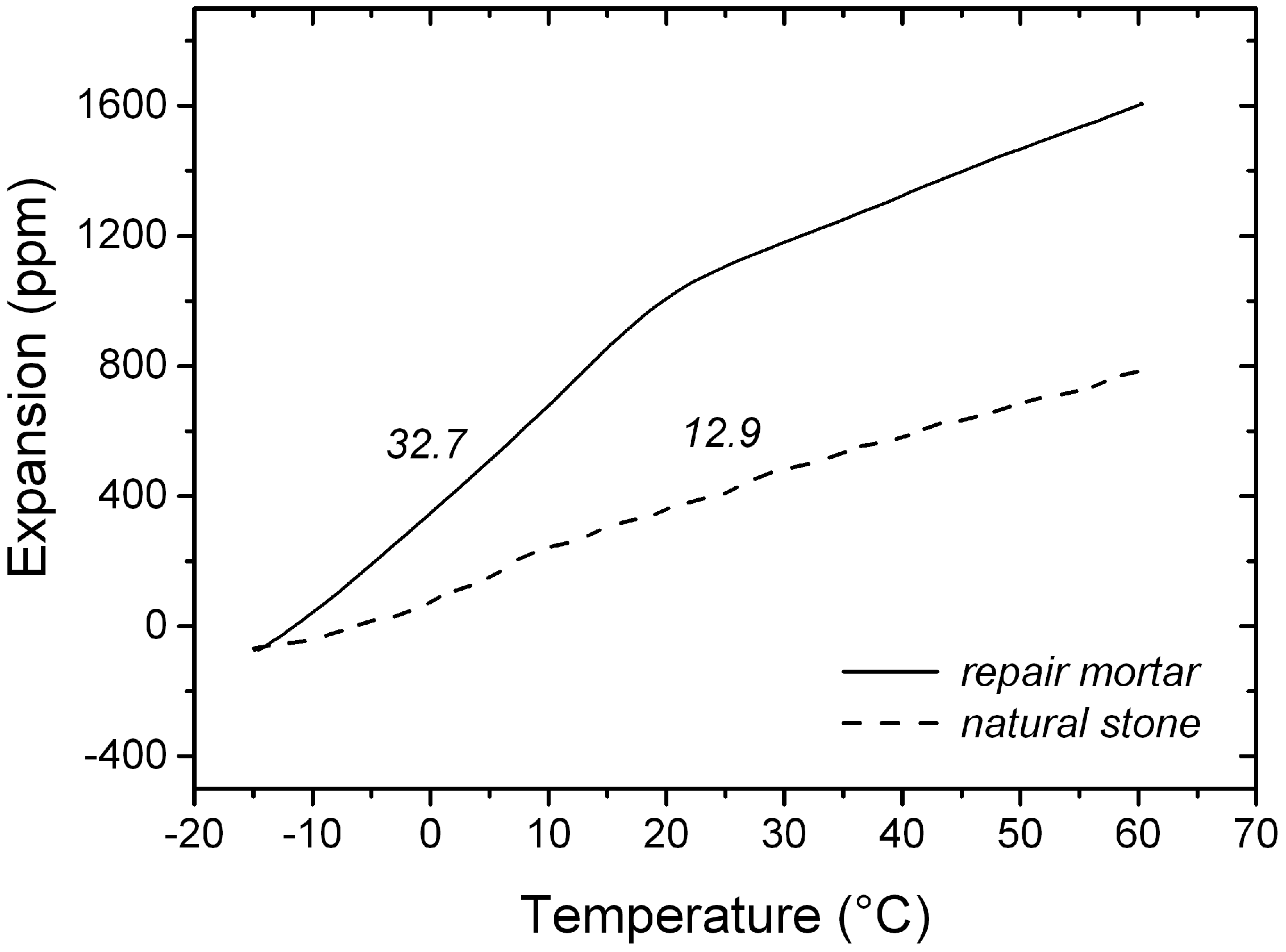

The linear coefficient of thermal expansion is roughly one third of the volumetric coefficient of thermal expansion and can be used to calculate the total linear thermal expansion of a rubber part over a temperature range. These forces are generated by thermal expansion of the rubber and or swelling effect of a fluid. Thermal expansion is the tendency of matter to change its shape area volume and density in response to a change in temperature usually not including phase transitions. In this study rubber was used as an additive to tune the thermal expansion behavior of various plastics.

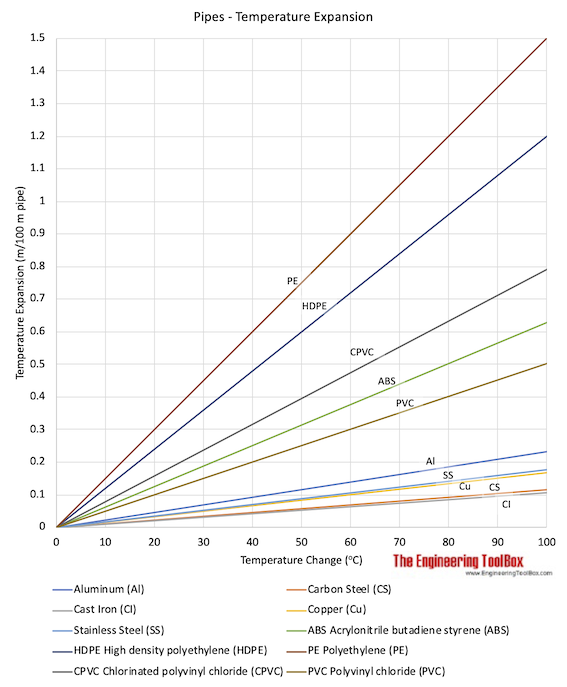

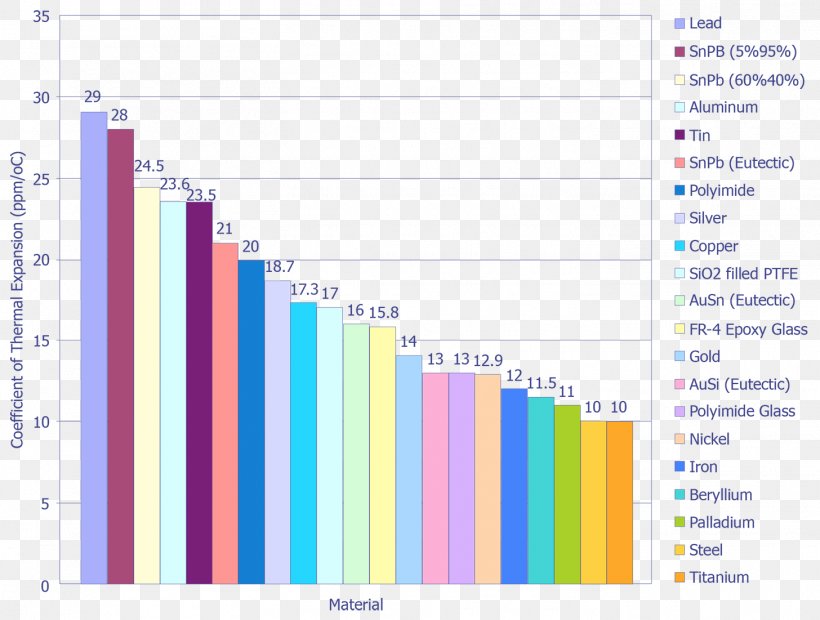

α g t g 0 08. The thermal expansion coefficients of a polymer in its rubber state can be estimated with the boyer spencer rule 3. 10 6 m moc 1 μm moc m m meter per meter in in inches per inches most values for temperature 25 oc 77 of. List of thermal expansion coefficients cte for natural and engineered materials mse supplies is a leading supplier of high quality materials equipment and materials characterization services for advanced materials research and manufacturing.

α r t g 0 164. Thermal expansion coefficients for some common materials. Understanding the relative expansion contraction characteristics of materials is important for application success. We found that the boyer spencer rule often underestimates the expansion coefficient of the polymer in its rubber state and that the relation.

There have been instances where a seal has ruptured a steel gland due to expansion when heated.