Continuity Test For Lv Cables

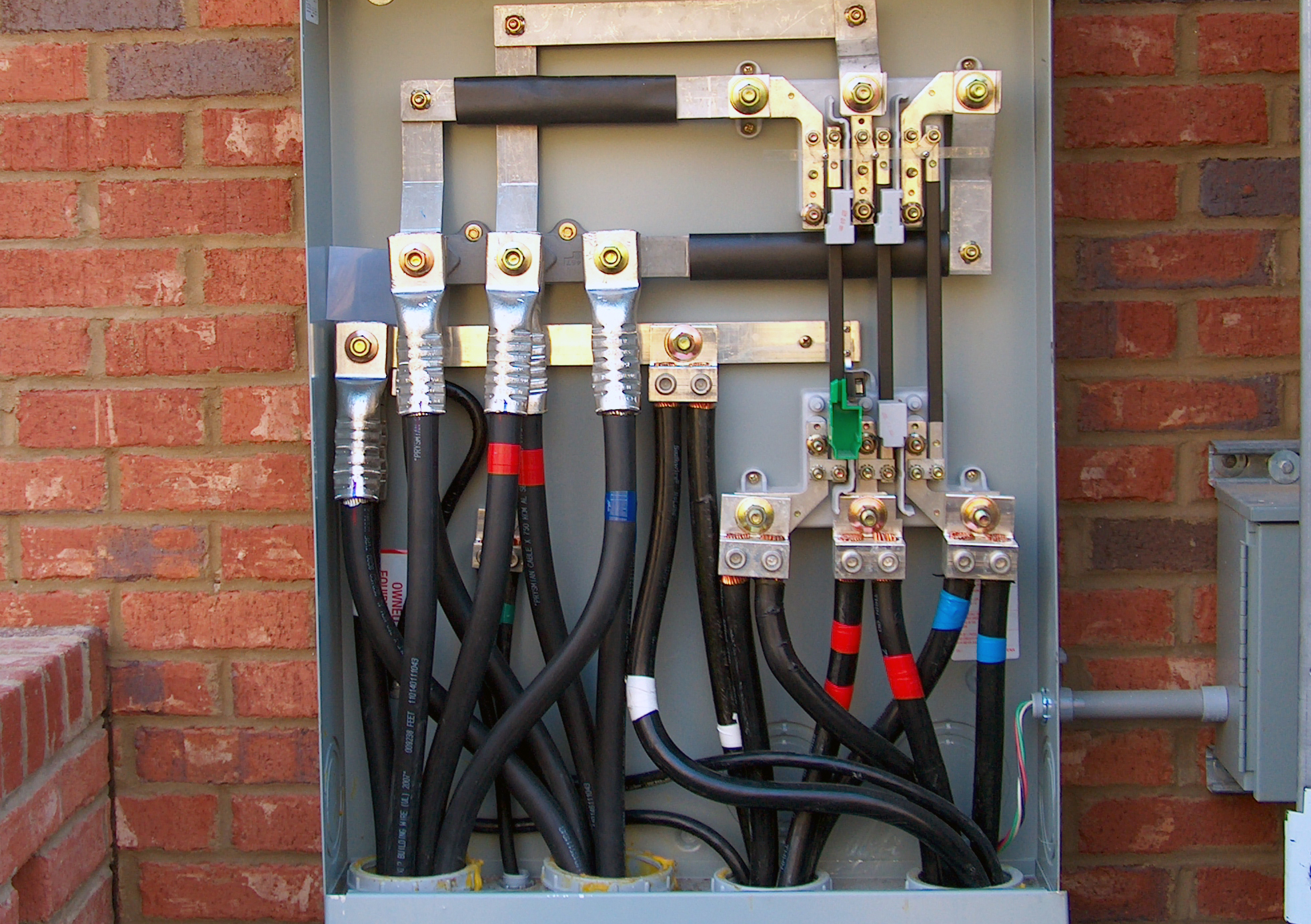

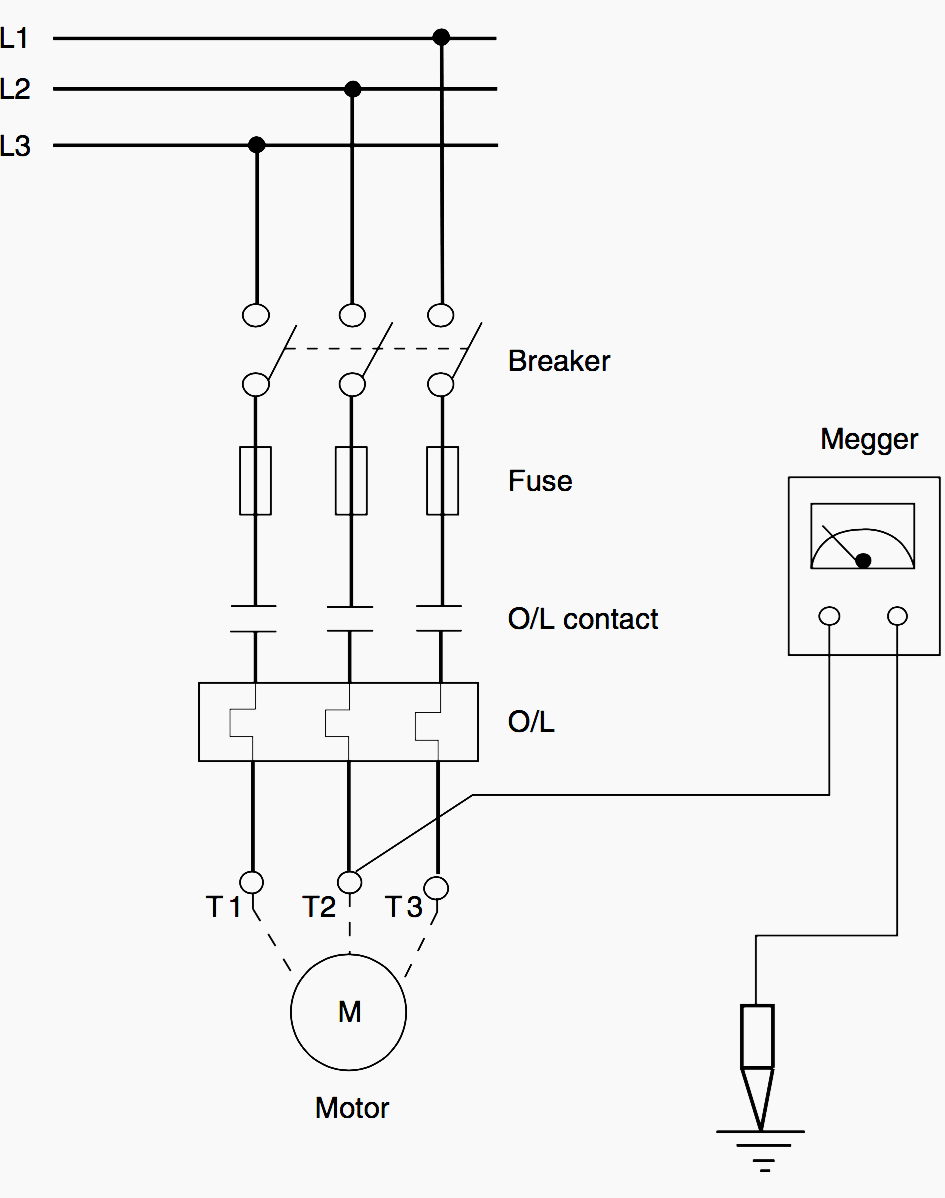

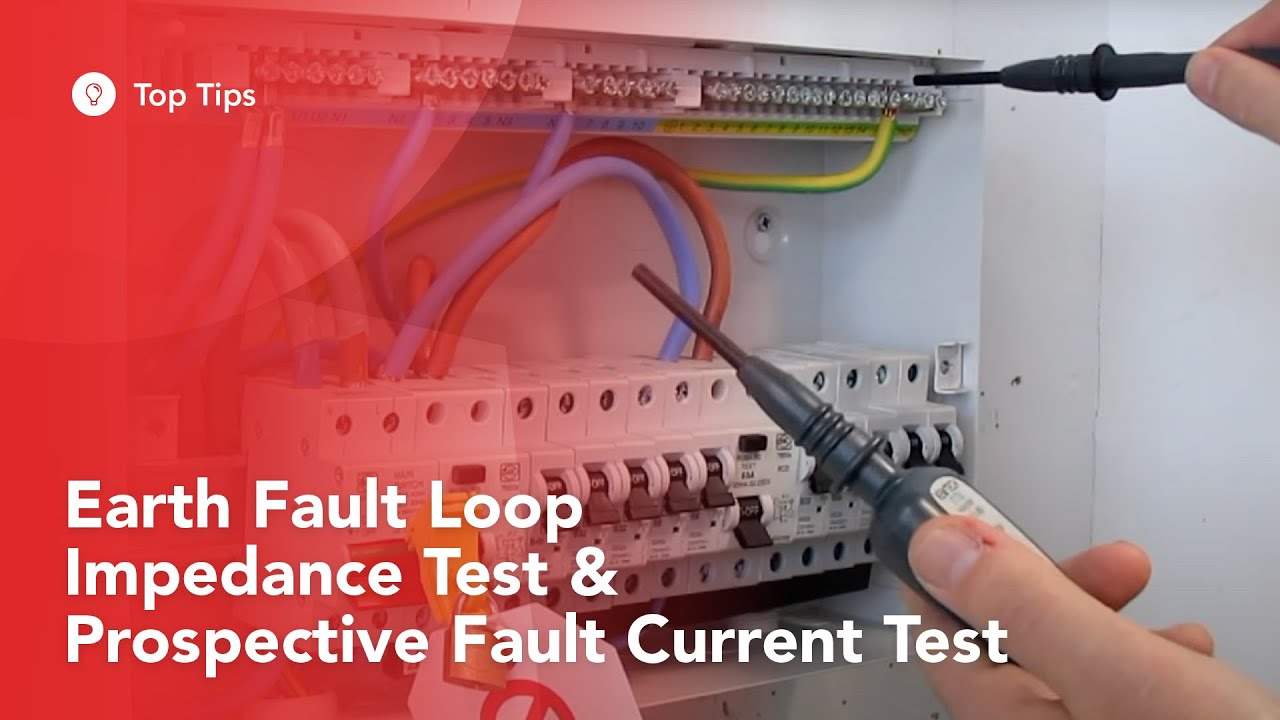

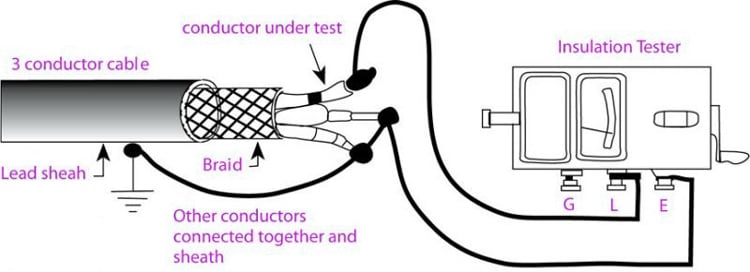

Perform an insulation resistance test individually on each conductor with all other conductors and shields grounded.

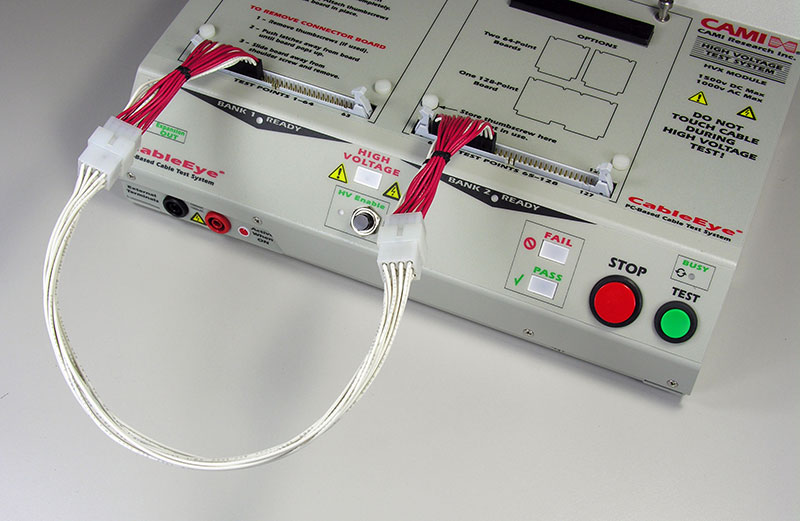

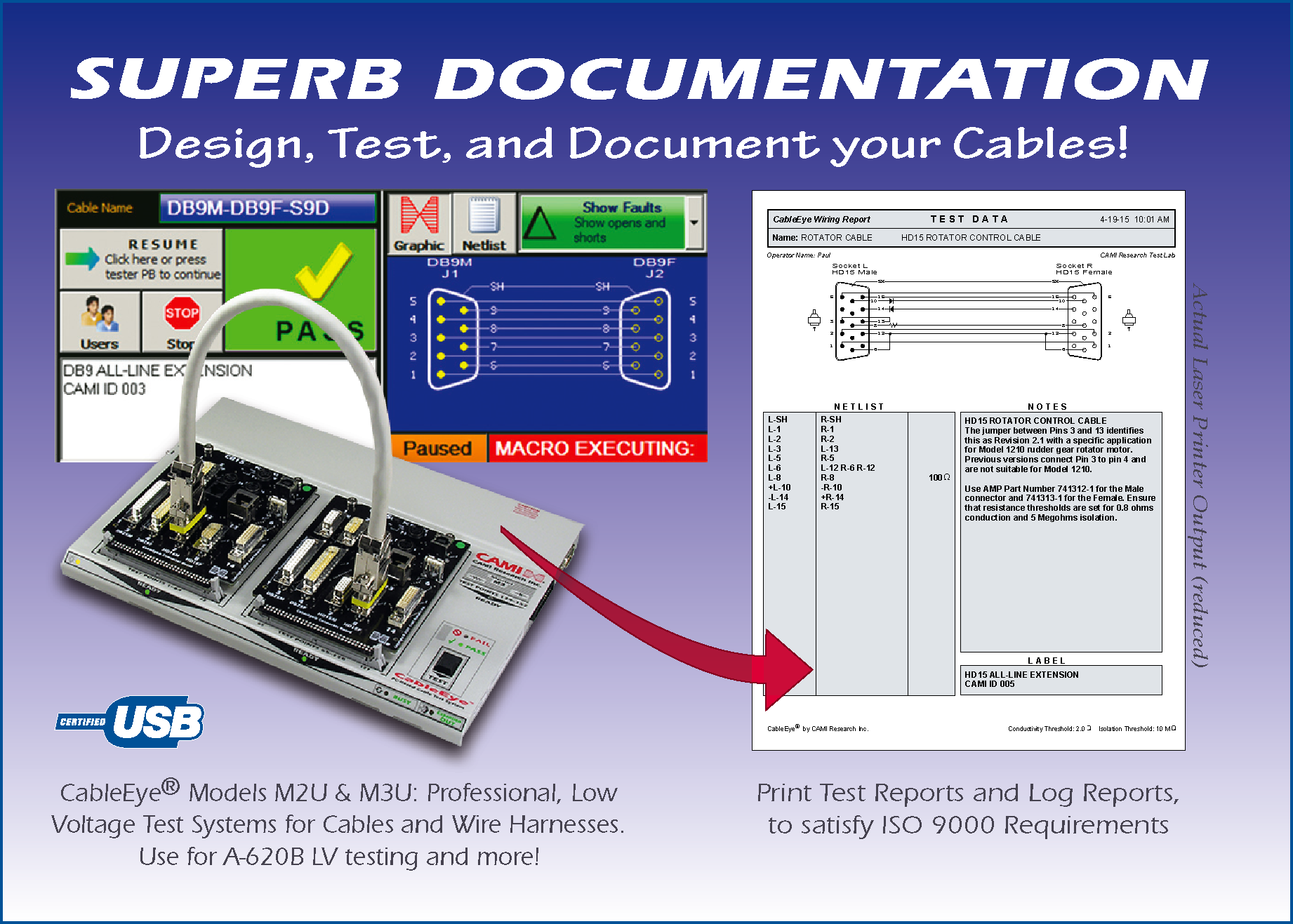

Continuity test for lv cables. Cable harnesses and aerospace cables must commonly perform point to point continuity tests and hipot tests as part of their routine production line tests. 1 compare cable data with drawings and specifications. Note these items on the test sheet. The continuity test also called low resistance measurement is measuring the low resistance of cables from 1 mω to 250 ω.

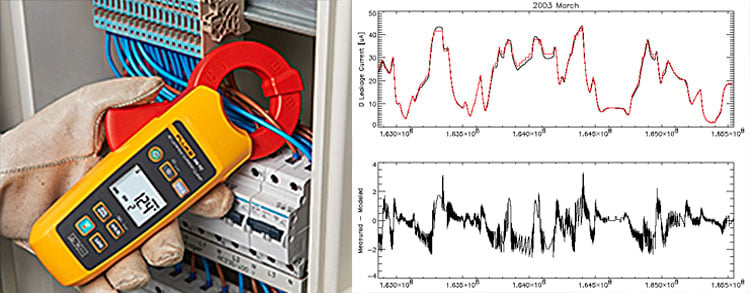

Continuity testing from shine detects the presence of a complete path for current flow. The following inspections and tests should be performed before energizing newly installed low voltage wire and cable rated 600v or less. Continuity test for different electrical electronic components devices. From simple two wire cables to custom cable assemblies and complex wires harnesses shine uses electrical testers made by cirris systems to ensure reliability and performance.

Pay attention to the number of sets the cable size routing and insulation ratings. Performing low voltage continuity tests. In the absence of manufacturer s published data use table 100 1. Perform continuity test to ensure proper cable connection.

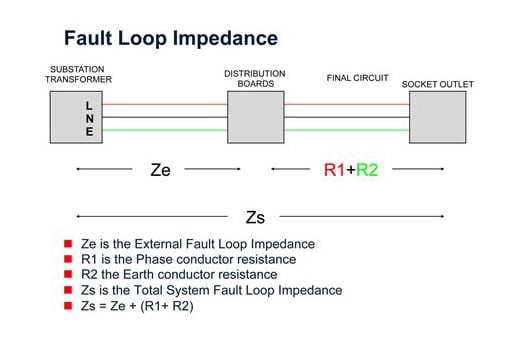

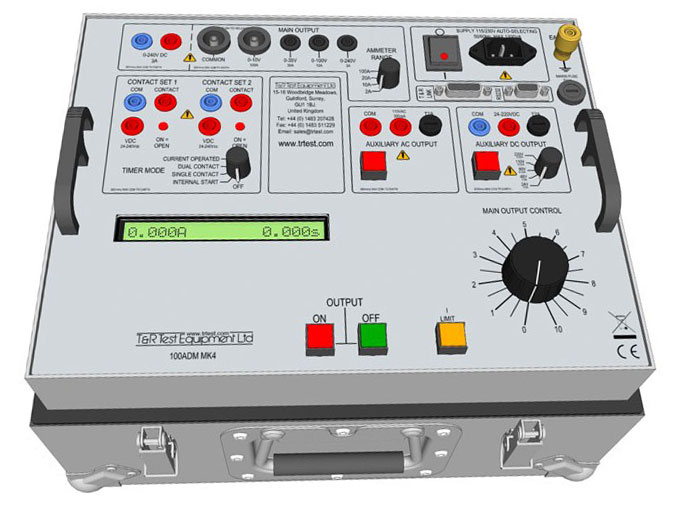

2 wires for resistances 1 ω and 4 wires for resistances 1 ω. Megger at 1000 volts for 1 minute. Low voltage and high voltage cable testing low voltage xlpe distribution cables. The minimum insulation resistance to earth or between phases shall be 100 meg ohms.

The instrument used for this measurement shall have a. In electronics electrical systems electrical wiring installations maintenance troubleshooting and repairing works. Cables shall be tested for insulation resistance with an insulation tester i e. The linking of a continuity test and hipot test when voltages exceed 1000 volts has previously only been available through custom test systems.

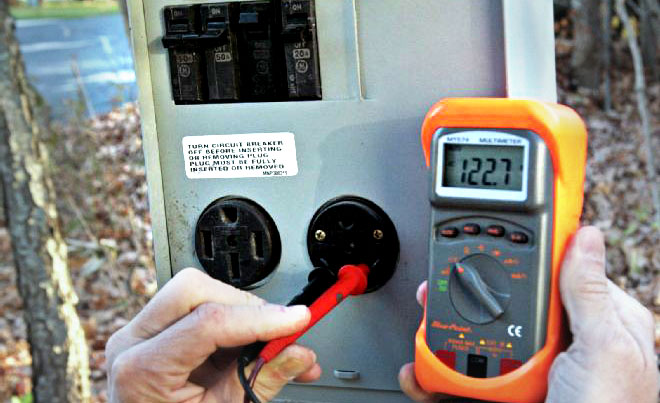

What is continuity test how to test for continuity. Testing continuity in a wire current or fuse is a good idea if you re installing or repairing any electrical components in an outlet fuse box car or appliance. 300 600 1000. A continuity test is checking of a circuit to see if the current can flow through it or not.

Perform continuity tests to insure correct cable connection. It basically determines if a circuit is open or closed. Perform insulation resistance test on each conductor with respect to ground and adjacent conductors. Equipment voltage rating recommended test voltage.

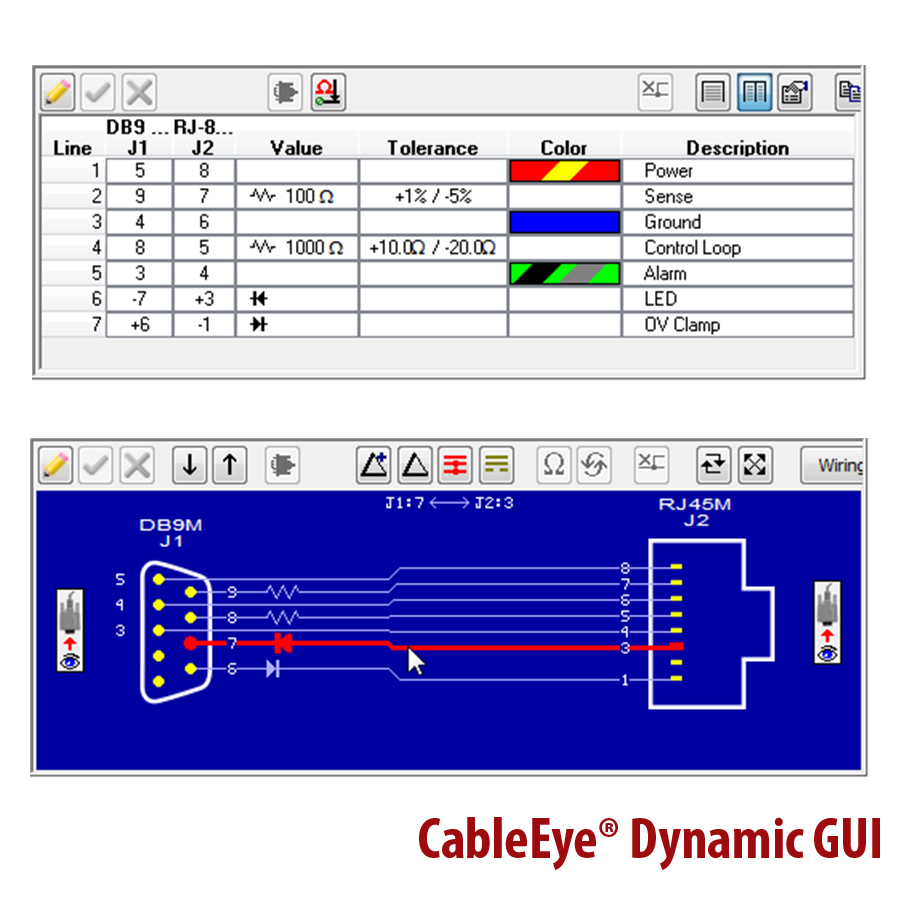

To test continuity all you have to do is stick 2 terminals on your multimeter against 2 ends of an electrical current. Perform a shield continuity test on each power cable. Applied potential shall be 500 volts dc for 300 volt rated cable and 1000 volts dc for 600 volt rated cable. The continuity test can be made in 2 or 4 wires according to the resistance to be measured.