Crane Slew Ring Bolts

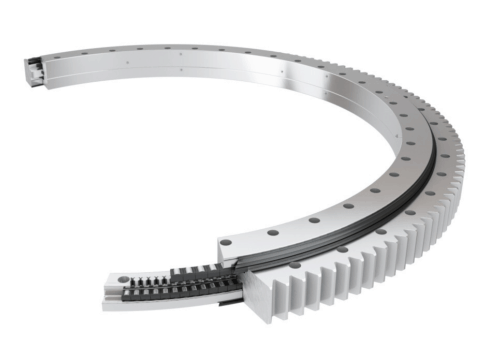

Depending on given requirements various sizes and designs are available.

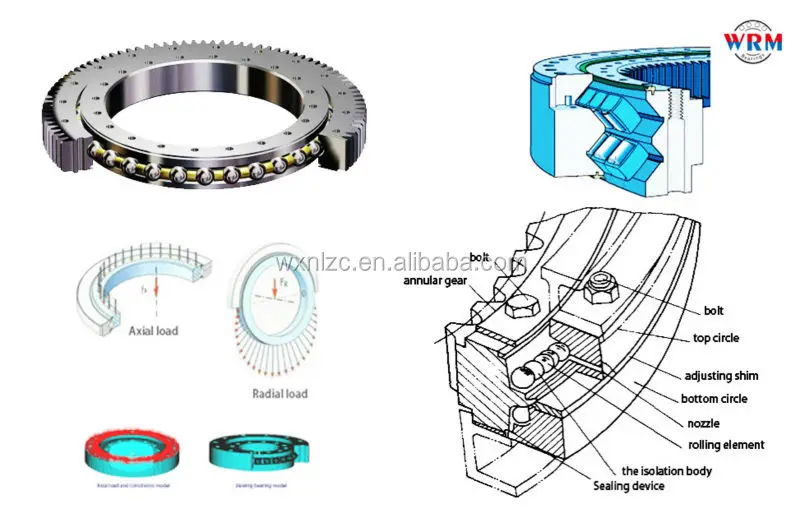

Crane slew ring bolts. For the crane to pivot through a full 360 degrees of rotation about a central pedestal the slew bearing provides the primary operational design requirements and sustains the full load of the crane its payload and counterbalance. The meshing condition should meet the requirements of the gear precision. The first thing i did when i got to the 450ft high top of a 2003 tower crane was to check the slew ring bolts with a 2lb beater using minimum force. Vtab content title.

Crane slewing bearing is importance maintenance due to have a complex load spectrum the slewing ring bearing can simultaneously handle all. Slew bearing condition monitoring. Before the bolt is fully tightened the meshing between pinion gear should be checked. Bolts and nuts are.

Money and extends the life of equipment. For a screw diameter d a nut height of 1 d is recommended. Slew ring bolts according to customer requirement and specification tested against 3rd party requirements including 100 mpi after hardening. On certain items for example slew ring bolts drive systems and braking systems within a reasonable preceding period as determined by a competent person the item may.

The slewing bearing is a large bearing that can withstand comprehensive loads. A regular schedule of raceway lubrication torque checks on bolts and gear lubrication is necessary even if the equipment has been idle. Many slew bearing condition monitoring techniques are available. We offer crane fasteners globally in qualities 8 8 10 9 and 12 9.

With the crane balanced off i started with the top row the slew bearing and when i struck the third bolt it moved showing it was loose. The slewing bearing also called slewing ring bearing is a new type of mechanical component. They consist of a bolt nut and hardened washer and on occasions a spacing sleeve. Where there is documented evidence that inspection and testing has been carried out.

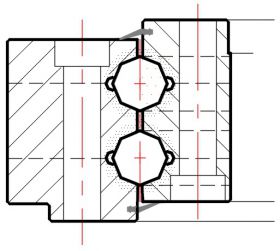

All of the components should be manufactured from high strength materials. Use high strength bolts and nuts to connect the slewing ring of the tower crane cross tightening to keep balance. Use double nut to tighten and prevent loosening. Rollix recommends the use of high tensile bolts grade 10 9 and exceptionally grade 8 8 or 12 9.

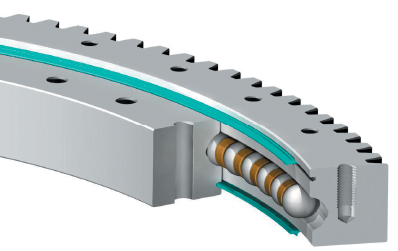

It can withstand large axial and radial loads and overturning moments at the same time. Bolts quality the iso 898 1 standards define the bolting grade adapted to structure assemblies such as slewing rings. There are two rows each with 59 bolts. High tensile bolt connections are used on tower crane joints including those on mast jib and slew rings bearings.

Definition of slewing bearing. It consists of inner and outer rings and rolling elements. Intervals according to the crane manufacturer s instructions.