Crane Slew Ring Failure

When lubrication is inadequate surface damage in the form of roughening or waviness occurs.

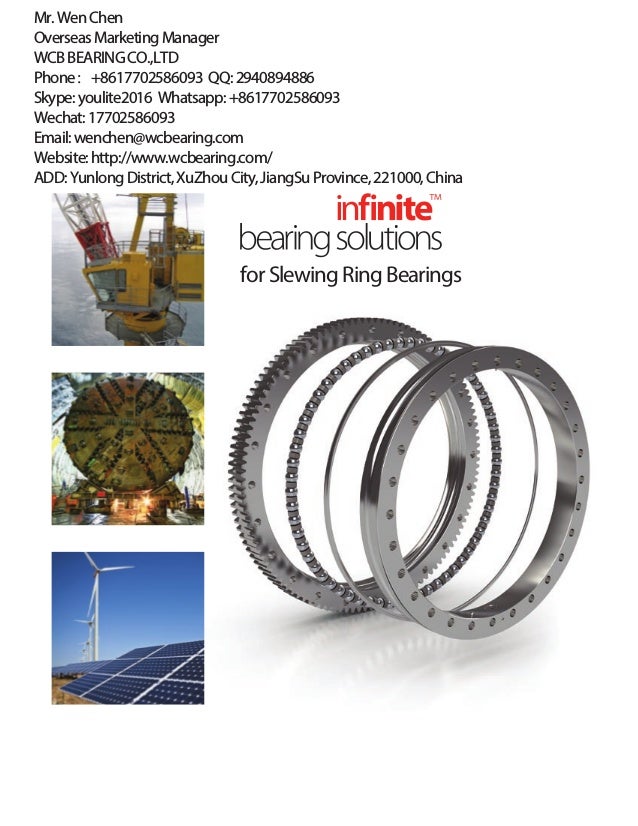

Crane slew ring failure. In slewing ring bearings a heavy duty extreme pressure grease is required. In slewing ring bearings a heavy duty extreme pressure grease is required. Shengbao road the third industrial part tongshan economic development zone xuzhou jiangsu china 221116. The measurement could be done from the inside and outside of pedestal.

More than 96 of slewing ring failure could be avoided by following simple maintenance tips. To slew means to turn without change of place compared to other rolling element bearings slewing bearings. Inadequate lubrication is the most common cause of premature bearing failures. These surface failures occur much earlier than classical fatigue failures and are less predictable.

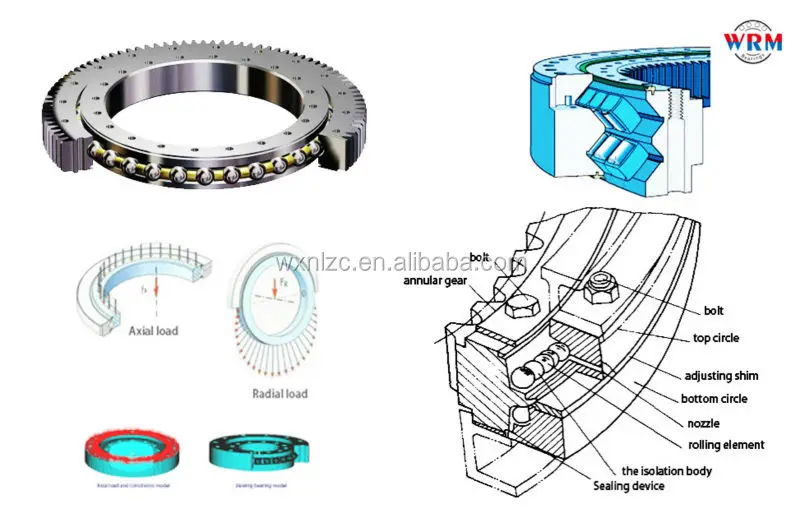

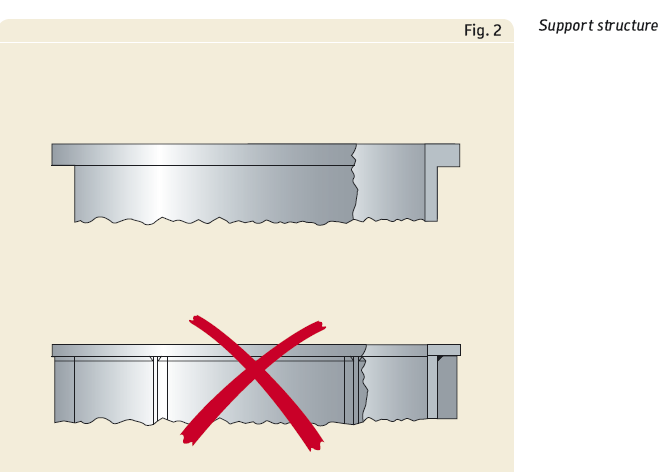

Introduction hoisting lowering jib radius hook or load luffing up luffing down operators cab centre of rotation slewing rotating turret slew ring connection fixed pedestal fig 1 the general movement of a pedestal crane. The slewing bearing rocking test should be done periodically for the bearing wear tracking and early failure detection. If the equipment is not in the appropriate good condition failures are likely to occur during cargo operations. Bottom rotation and top rotation.

Fortunately no one was injured other than the crane operator who escaped with a broken ankle. Follow the maker s recommendations and conduct the test at the same check points as during the initial test during commissioning in order all subsequent. Based on the preliminary investigation it was found that the failure of bolts and nuts at the slewing ring has caused the collapse of the boom slewing table and cabin. Of 1000mm 2000mm 1250mm 1064mm are both standard.

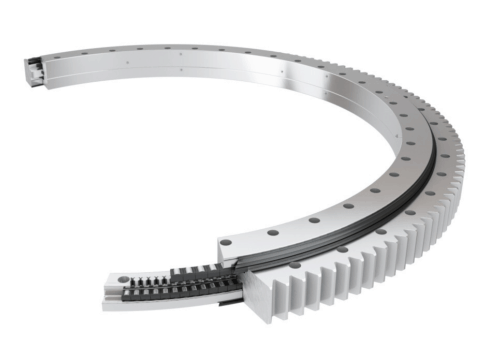

The tower crane use a single row four point contact ball elements slewing ring 01 series and double row ball slewing bearing dia. When lubrication is inadequate surface damage in the form of roughening or waviness occurs. Crane safety especially related to the failure of critical components such as bolts and nuts load sensor and wire rope is under scrutiny. Apply a liberal shot of extreme pressure grease to the fittings around the bearing s circumference at intervals recommended in the operator s manual.

Six steps to save slewing ring bearings. It is divided into two types for slewing bearing. These surface failures occur much earlier than classical fatigue failures and are less predictable. The failure of the crane s slewing ring led to the crane body collapsing into the cargo hold.