Crane Slew Ring Inspection

The towers can be further classified as being mono towers inner and outer towers and telescopic towers.

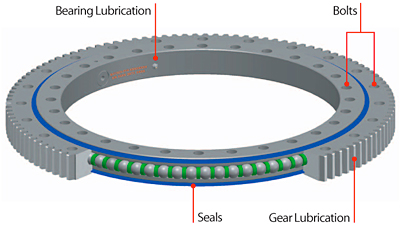

Crane slew ring inspection. As with all important machine components slewing bearings should be cleaned and inspected regularly. Application advantages being proactive about asset integrity can be the deciding factor in whether operations are unexpectedly halted. In applications where there are heavy loads and or high levels of contamination decrease the time between inspections. Quality control is carried out by alatas personnel from the forging to the packaging of the finished product according to class procedures.

The tower crane use a single row four point contact ball elements slewing ring 01 series and double row ball slewing bearing dia. Where there is documented evidence that inspection and testing has been carried out. Crane slewing bearings manufacture and installation alatas offers high quality slewing bearings at reasonable prices and with delivery times of 60 to 90 days. We are able to provide our clients with a peace of mind whenever they conduct any lifting operations with providing this detailed inspection which covers all parts of the crane listed as below.

The inspection is fast allowing for up to three cranes having slewing bearing of 2300 mm diameter to be reviewed on one date with limited preparation. The measurement point is measuring point on the rear of the deck crane if the measurement is performed inside the fixed post place the dial gauge on the inside surface of the fixed post and apply the probe to the bottom surface of the base plate of the deck crane. We can provide independent service for you. Of 1000mm 2000mm 1250mm 1064mm are both standard.

Surface of the outer ring of the slewing ring. On certain items for example slew ring bolts drive systems and braking systems within. Maintenance intervals depend entirely on the operating conditions. First of all we will evaluate the current condition of the slewing bearing and point out the abrasion trend adjust the maintenance plan issue the inspection report which including the immediate measures to be taken the possibility of using it and perfect service plan.

And maintenance at more frequent intervals for example at annual and other inspection intervals according to the crane manufacturer s instructions.