Crosslink Density Of Rubber Calculation

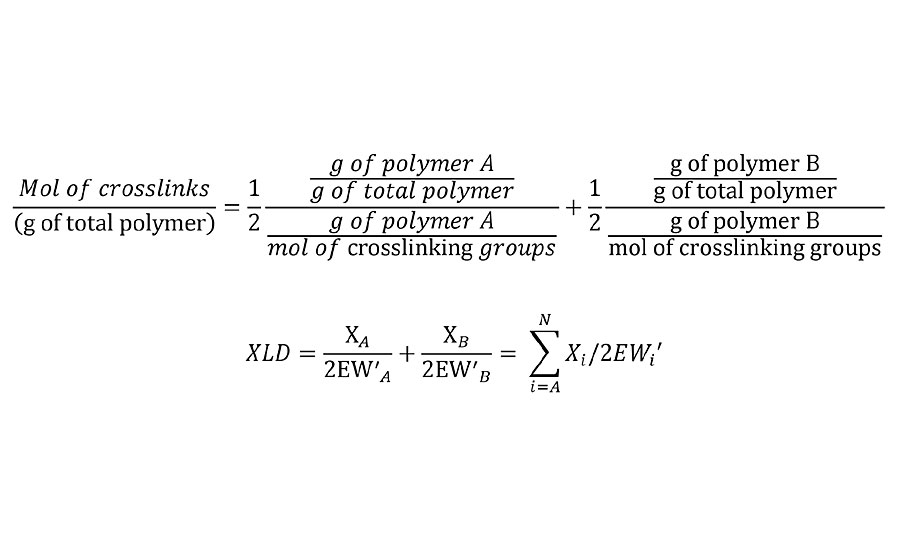

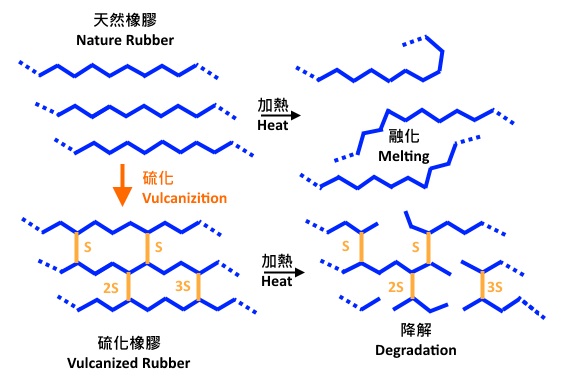

Crosslink density is used to measure the degree of crosslinking between rubber and sulfur.

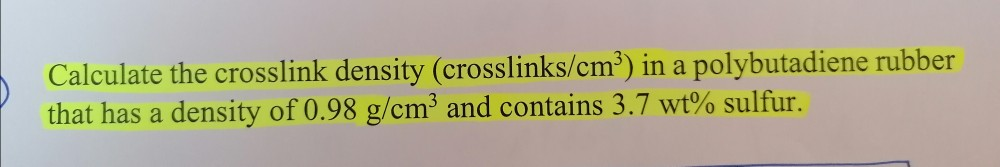

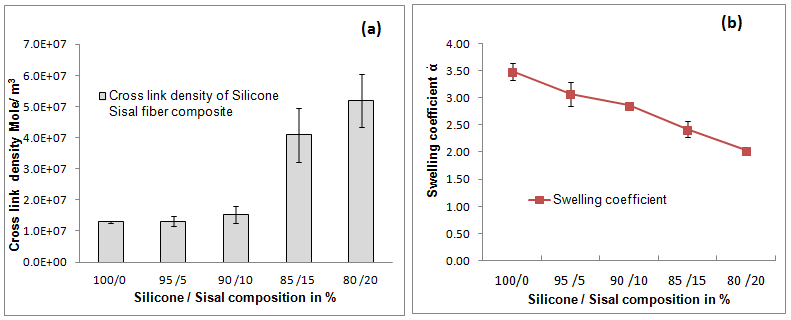

Crosslink density of rubber calculation. In papers on the theory of rubber elasticity the symbol for crosslink density and its definition became. The rubber modulus determined from dynamic mechanical analysis is a measure of the effective cross link density of polymers. As crosslinks increase the rubber molecules eventually become insoluble in solvent and hence the force needed to break the rubber is significantly higher as chemical bonds have to be raptured. In his benchmark paper p j.

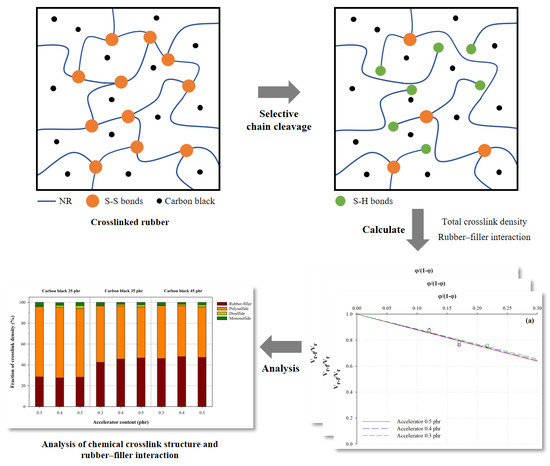

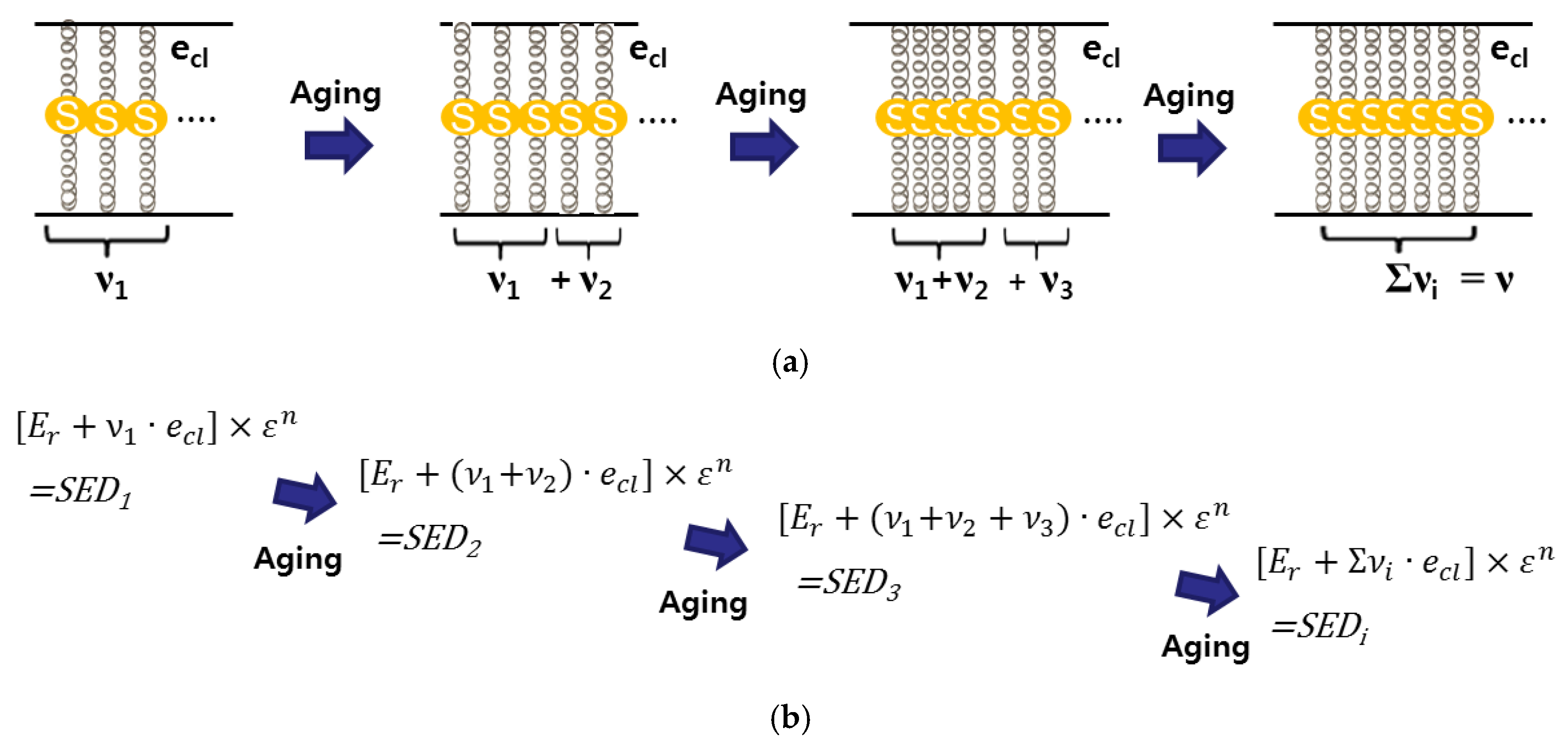

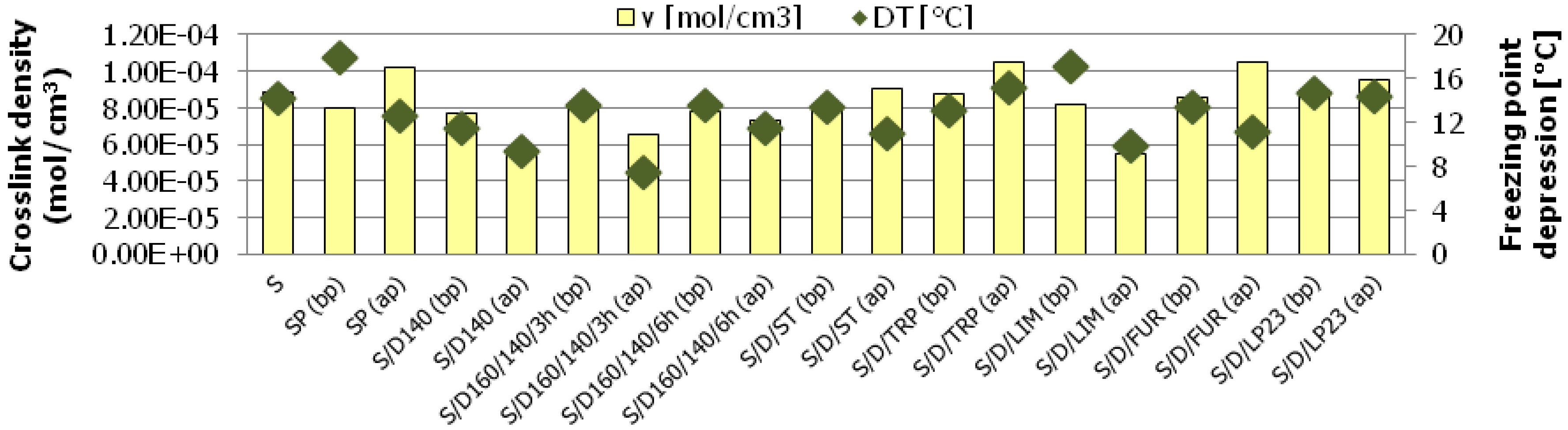

And empirical equations were derived which relate compression deflection and effective crosslink density of toluene swollen specimens of silicone rubber. Natural rubber nr vulcanizates with different crosslink densities were obtained through using different sulfur and accelerator amounts and different accelerator types. Calculate s the entropy per chain in terms of r0 2. The degree of crosslinking is affected by temperature pressure and the time of heating time.

The chemical interaction between sulfur and rubber is called crosslink. He also correctly taught a method to calculate the number of elastically effective chains v based on the molecular weight mn of the rubber prepolymer and the molecular. However strength does not increase indefinitely with increasing crosslink density. Flory huggins solvent interaction parameters have been calculated.

The crosslink density was characterized by an 1 h nmr technique and its influence on mechanical properties such as shore a hardness 300 modulus. Flory1 used statistical mechanics to relate the elastic modulus of a polymer network in the rubber phase to the number of elastically effective chains and related this to the crosslink density. A method was developed to accurately measure the compression and the deflection of swollen rubber specimens. These conditions will determine the flexibility behaviors of the final rubber.

The cross link density is defined by the density of chains or segments that connect two infinite parts of the polymer network rather than the density of cross link junctures. The study on influence of total crosslink density on shore a hardness and 300 modulus of nr vulcanizates showed that they both increased linearly with the crosslink density the slopes were 2 7 3 0 cm 3 10 5 mol and 0 27 0 31 mpa cm 3 10 5 mol for shore a hardness and 300 modulus respectively whether the crosslink density. For sulfur crosslinked natural rubber n r my students used to determine the crosslinking density or the percentage of sulfur incorporated by dividing the number of moles of sulfur used. Consider the gaussian statistics for the distribution of end to end distances.

Assume local and macroscopic deformations are the same affine deformation. Theory of rubber elasticity approach and results. Crosslink density is an important structural parameter for cured rubber.