Crumb Rubber Asphalt Mixtures

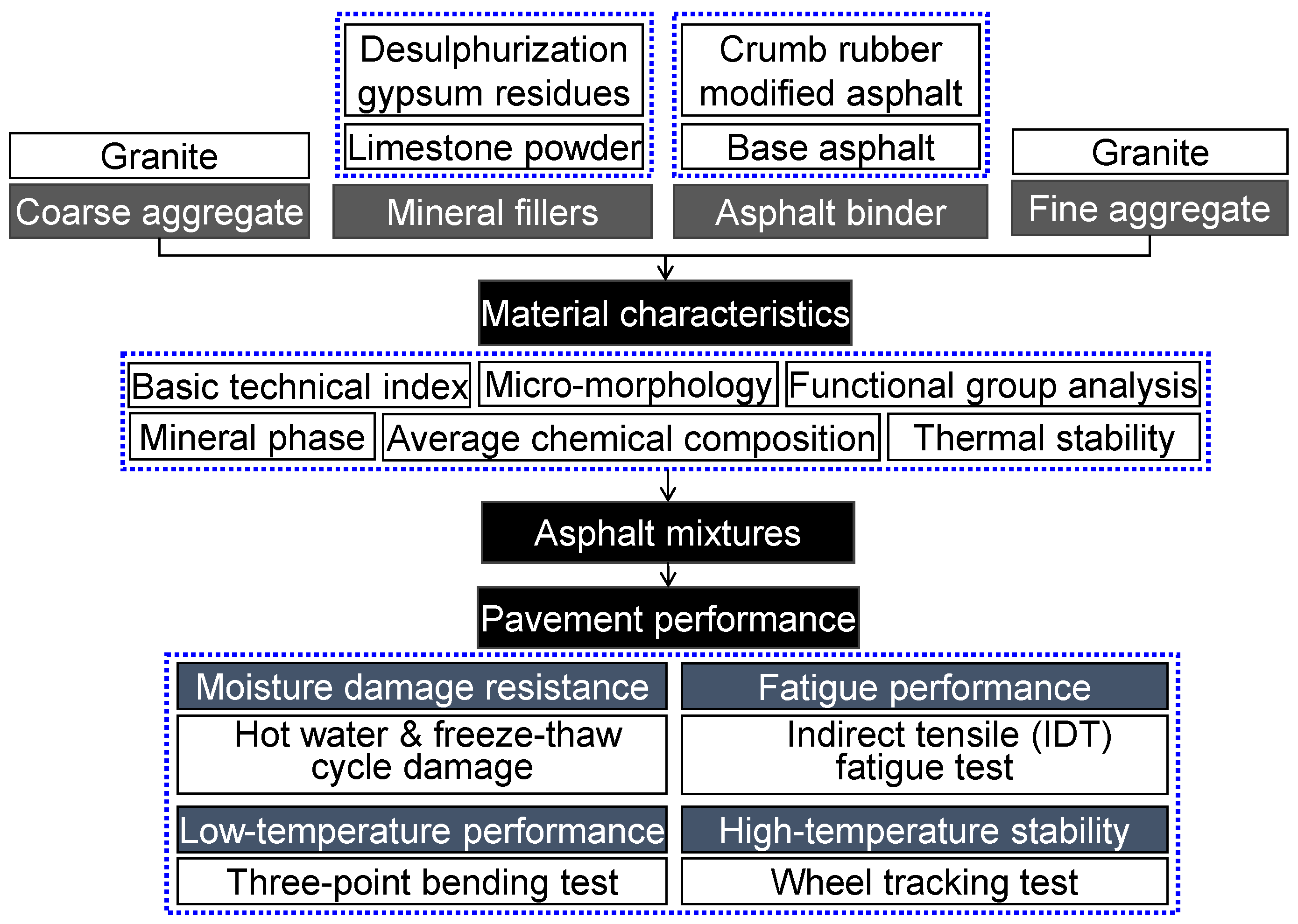

There are two different processes using crumb rubber in the asphalt mixtures a dry process and a wet process.

Crumb rubber asphalt mixtures. Cooper iiid samuel b. Dry process refers to mixing crumb rubber into the mixture as a small part of the aggregate or filler rather than blending the rubber with the liquid asphalt. This article addresses the 8 years behaviour of a crumb rubber asphalt mixture produced by the dry process ardry. D and gaylon l.

Structural and functional characteristics of the pavement were surveyed at the opening to traffic after rehabilitation 2009 and 8 years after 2017. Impact of various crumb rubber modifications on asphalt binder and mixture properties. The purpose of this study was to investigate the effect of adding crumb rubber to asphalt mixture using wet process. Two test temperatures were selected for the dynamic modulus test.

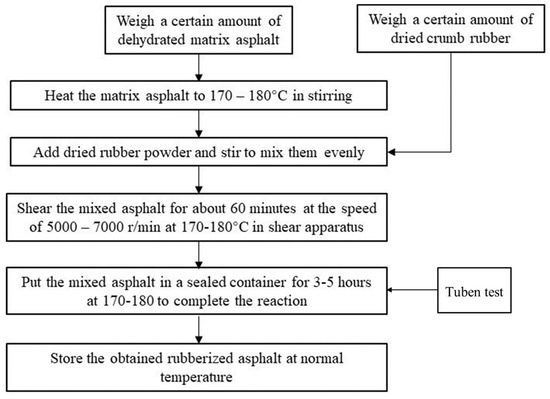

Of chemistry louisiana state university baton rouge la 70803. This paper provides an overview of crumb rubber modified asphalt mixtures with particular reference to the dry process. Later on in the 1970s the idea evolved into the use of ar as slurry applied over the whole surface. The dry process involves the blending of crumb rubber with hot aggregates.

Crumb asphalt rubber mixtures produced by the wet process arwet 2 1. The ability of crumb rubber to improve the asphalt mixture performance depends on many factors such as the mixing methods reaction time with bitumen nature of the rubber and size and concentration of the rubber particles. Dalya ioan negulescuc samuel b. Rubberized asphalt is a term applied to rubber modified asphalt with less than 15 percent by total weight of the asphalt cement.

The oral presentation was made by william daly. This fact reveals that is feasible to use a high tire crumb rubber content with a 70 100 penetration. The crumb rubber content varies from 0 10 20 to 30 at the static modulus test. The results indicated that the crm asphalt mixture performs better than the standard asphalt mixture on dynamic behavior rutting resistance cracking resistance and moisture stability.