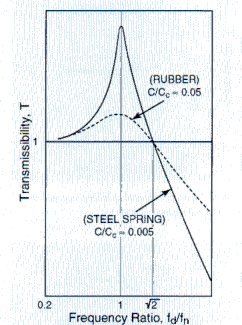

Damping Ratio Of Rubber

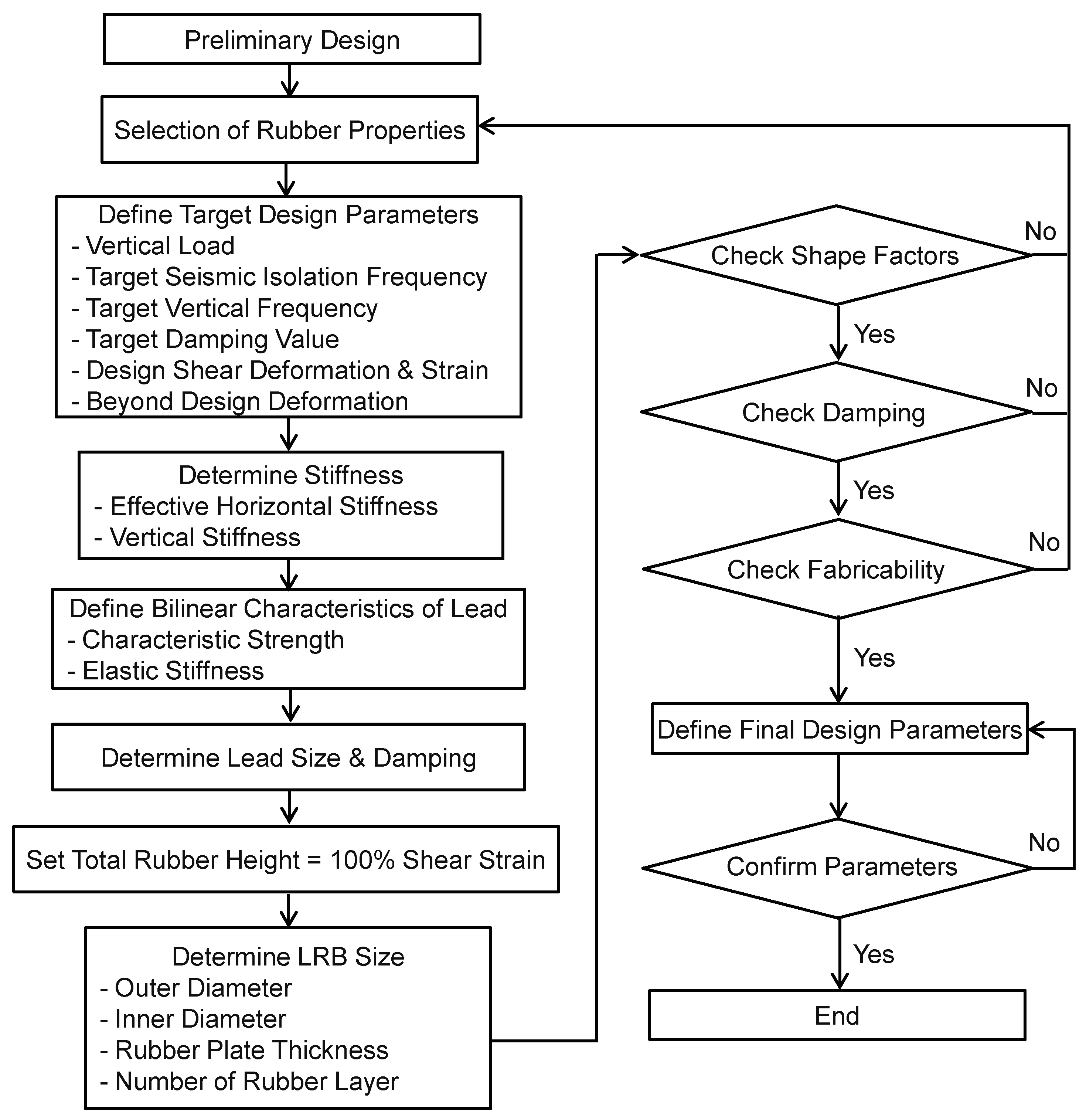

To a different frequency 2 altering the stiffness of the sprung system 3 altering the location of the repeated load 4 reducing the magnitude of the repeated load 5 reducing the dynamic amplification of the repeated load.

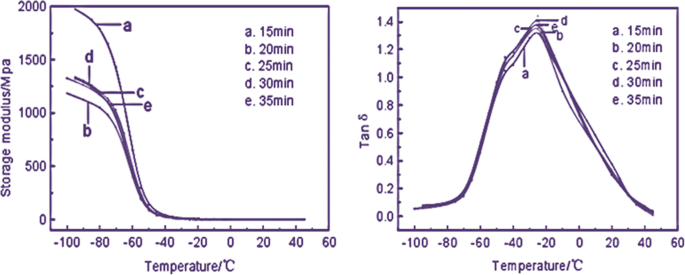

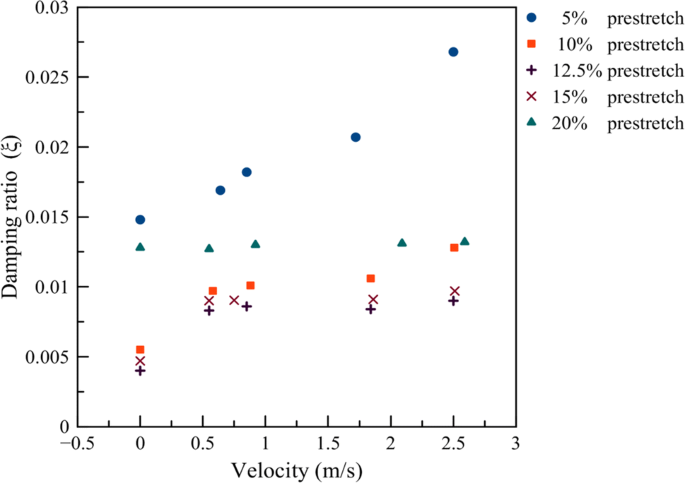

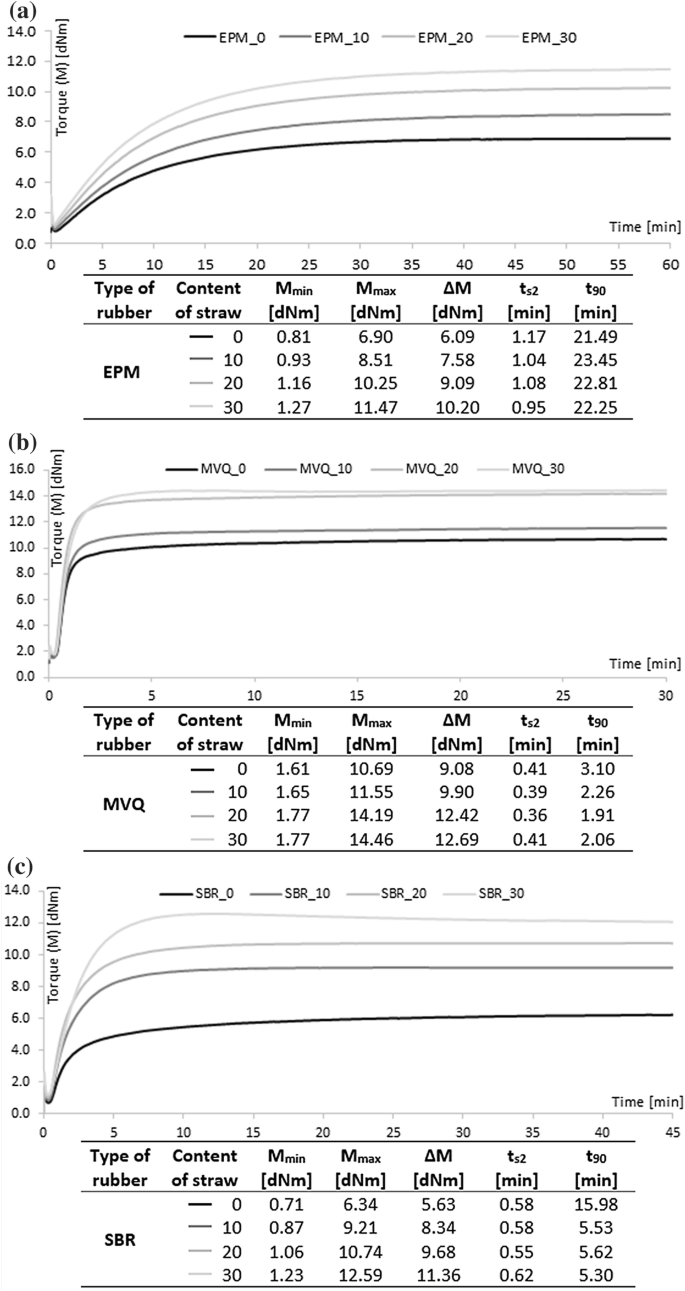

Damping ratio of rubber. Hammer test was performed by varying the rubber thickness to find the damping ratio using logarithmic decrementcurve damping ratio ofthe rubber iscalculated fromthe logarithmic decrement plot of displacement as expressed in equation 1. This study examines the small strain dynamic properties of mixtures composed of sandy and gravelly soils with granulated tire rubber in terms of shear modulus go and damping ratio in shear dmin. Material damping ratios bare structure system viscous damping ratio ξ composite 0 002 to 0 003 steel 0 001 to 0 002 c 1. And damping of rubber element ladislav p ust ludˇek peˇsek frantiˇsek vanˇek jan cibulka a sample of rubber element used for reduction of noise and vibrations of tram and railway wheels was loaded by harmonic force at different frequencies 10 20 30hz and amplitudes in the range 0 25 2 25kn and by a constant preload 6kn.

A percentage damping of for example damping 30 mean that 30 of the total energy imposed on the rubber material is absorbed by the rubber material i e. In order for the motion to be periodic the damping ratio must be limited to the range 0 le zeta 1. Rubber 0 05 large buildings during earthquakes 0 01 to 0 05 the data in tables 4 through 6 is taken from reference 3. With synthetic rubber e g.

For a damped harmonic oscillator with mass m damping coefficient c and spring constant k it can be defined as the ratio of the damping coefficient in the system s differential equation to the critical damping coefficient. Note that additional values for concrete are given in appendix a. 1 altering the natural frequency of the sprung system i e. The damping ratio provides a mathematical means of expressing the level of damping in a system relative to critical damping.

Butadiene rubber the value are higher for soft grades but are almost identical for harder grades. Viscous damping ratio ξ metals in elastic range 0 01 continuous metal structures 0 02 to 0 04 metal structure with joints 0 03 to 0 07 aluminum steel transmission lines 0 0004 small diameter piping systems 0 01 to 0 02 large diameter piping systems 0 02 to 0 03 auto shock absorbers 0 30 rubber 0 05. Here omega 0 is the undamped natural frequency and zeta is called the damping ratio. ξ 1 2πn ln ai aiþn 1 where a is the amplitude of the displacement and n is the nth cycle of decrement.

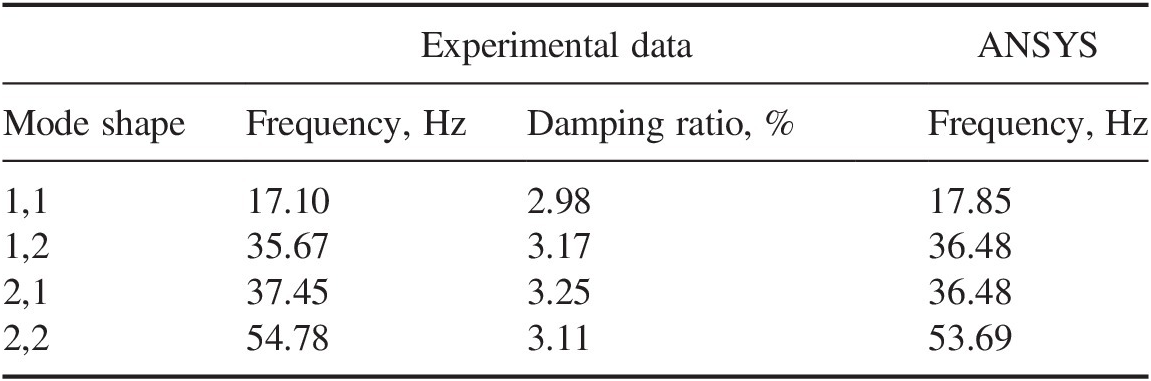

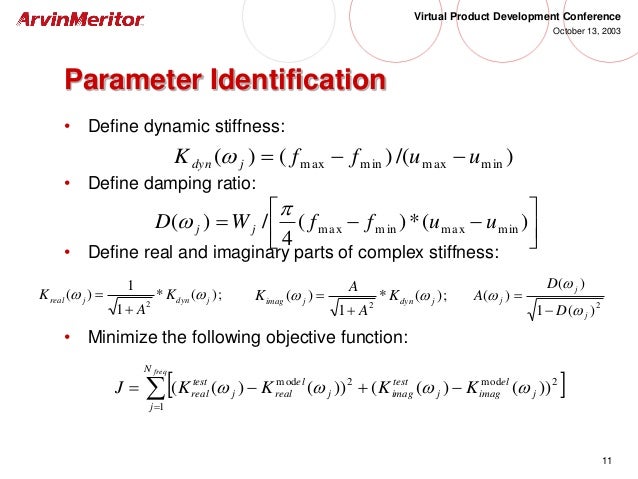

Torsional resonant column tests are performed on dry dense specimens of soil rubber mixtures in a range of soil to rubber particles size 5 1 1 10 and rubber content from 0 to 35 by mixture weight. In this paper finite element modal analysis is used on square natural damping rubber plate with various boundary conditions to determine its dynamic properties and damping coefficients α and β.